FDA will allow using a pc to perform Element of the PAR by operating a computer plan that culls out analytical facts from Each and every batch to perform a pattern Investigation (16). FDA does not allow for the usage of a computer to carry out the complete assessment of the development information.

in the case of integrated valves, traceability must be ensured for every valve. Information really should contain especially the type of integrated valve (such as the version), the person identification reference on the valve, the identify of the manufacturer, the date of the final (or upcoming) preventive servicing and facts of any preventive upkeep executed within the valve.

PQR decides the necessity for producing method variations, in-process controls and technical specs. This features identification of advancements into the product and production course of action dependant on trend Assessment and threat assessment.

thirteen. What are the GMP specifications relevant towards the comminution and initial extraction measures in the manufacture of non-transgenic comminuted plants and herbal extracts utilized as Energetic substances?

Qualification standing of areas, equipment and systems and their influence on production procedure validation and analytical methods

as they don't give a similar standard of assurance as on-site assessments, but do take that they have got a part to play inside of a danger-centered tactic.

The doc 'advice about the events when it can be suitable for skilled authorities to conduct inspections with the premises of manufacturers of Lively substances utilized as starting up supplies', printed as Section of the Community processes, states that it is expected that manufacturing-authorisation holders will attain assurance the active substances they use are made in accordance with GMP via audit in the Energetic-compound suppliers. Tiny makers might not have the mandatory skills or resource to perform their particular audits.

The CGMP has prolonged required responsible people today to review info making sure that systems are operating and outputs satisfy acceptance conditions. This is a fundamental basic principle of technique control. Organizations really should leverage the knowledge that they are at present capturing to show that equipment and utilities qualification is less than control. The modular strategy may be utilized by consolidating, summarizing, and/or referencing vital knowledge from applicable get more info techniques to provide inside assurance that tools and utilities qualification, throughout a product form, meets the requirements from the EU PQR.

Storage situations all through transportation should be validated or monitored using an appropriate temperature-measuring product that is definitely effective at displaying fluctuations in temperature e.

Details integrity should be ensured by suitably applied and chance-assessed controls. The calculations along with the information should be secured in this type of way that formulations will not be accidentally overwritten.

The Expert Skills Registry Summary report has a brand new column labeled Competency which displays the Main competencies an educator’s Qualified growth addressed. Place is now a fall-down checklist which has a Assist Icon that hyperlinks to definitions of the positions.

The collective endeavours of various departments are check here important for the thriving execution of APQR, and also the report created contributes drastically to selection-making in the least amounts.

A immediate composed deal should also be set up among the MIA holder accountable for QP certification of your product and internet sites involved in the different stages of manufacture, importation, screening and storage of the batch prior to it undergoes certification (hereafter: deal makers).

In such cases, the general accountability for suitable manufacture of the batch lies While using the QP accomplishing closing certification on the batch ahead of release for sale. It is usually doable that, at an individual producing web-site, distinctive QPs could possibly be accountable for certification of various phases of manufacture of your batch.

Amanda Bynes Then & Now!

Amanda Bynes Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Suri Cruise Then & Now!

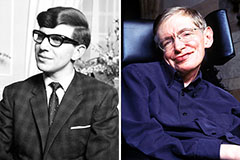

Suri Cruise Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!